Major New Release of SURFCAM Verify Includes Machine Tool Simulation

(Westlake Village, California, USA – August 27, 2002) Surfware, Inc., makers of SURFCAM CAD/CAM systems announce a new release of their integrated toolpath verification software, SURFCAM Verify 4.1. SURFCAM Verify uses solid models to display the material removal process for 2, 3, 4 and 5-axis milling and turning. Verification lets you detect errors on the computer without tying up the NC machine.

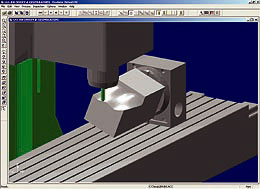

Topping the list of new features in SURFCAM Verify is Machine Tool Simulation. This add-on software package allows you to model your machine tool and have it simulate the entire machining process of your parts. This allows you accurate checks for collisions or limits that may not be visible with tool material verification.

New Open GL support gives you faster frame rates for dynamic rotations and faster rendering. Apply realistic finishes such as copper, graphite, steel, plastic, etc. to your parts. Colored lights, different light sources, ambient light and light intensity and distance can also be applied.

Other new features include:

-- Toolpath backplotting displays toolpath along with material removal allowing you to see what toolpath is affecting specific parts of the stock material.

-- The New Save/Load Model feature lets you save and reload a stock model at any point during the machining verification.

-- Now you can create videos (VRML files) of your machine simulation.

-- New Quick and Advanced CAD Compare gives you improved CAD to verified model comparisons.

-- Backstepping allows you to back up the verification process one cut at a time.

-- View Wireframe creates a wireframe tool allowing you to monitor tool movement without restricting the view behind the tool.

-- Enhanced machine tool support

-- Enhanced G & M code support for mills and lathes

-- Nested external Sub-program calls

-- Linear and grid hole cycles

-- G74 style face drilling for lathes

-- Supports up to four spindles per machine

The SURFCAM Verify system contains an integrated Predator Virtual CNC™ module, as well as Predator Editor™ with DNC communications functionality. Virtual CNC's innovative modeling technology offers faster verification and outstanding visualization of the machined part. This compliments SURFCAM's emphasis on speed and accuracy in its multi-axis toolpath operations.

About Surfware, Inc.

Surfware, Inc. is the manufacturer of SURFCAM® CAD/CAM software, built for the Microsoft® Windows® operating system environment. SURFCAM makes easy CNC programming of 2-, 3-, 4, and 5-axis mills, lathes, wire EDM, laser, plasma, and water-jet machines a reality. Machinists, designers and engineers worldwide use it for 2D and 3D mechanical design, surface modeling, solid modeling, reverse engineering, prototyping, mold-making, pattern-making and production machining. For more information, contact us at: www.surfware.com, email: info@surfware.com, telephone: 800.SURFWARE (North America) or +1.818.991.1960 (worldwide), fax: +1.818.991.1980 (worldwide).