Ingersoll Highlights Innovation At IMTS 2002

The newest innovation in composites is the "domes on" capability of the Ingersoll Automated Fiber Placement Machine (AFPM). The latest generation Ingersoll AFPM can place material completely over the end of a part rotating on the centerline of the headstock and tailstock, making it possible to create composite fuel tanks, and other barrel-shaped objects, complete with integral domes. This particular machine feature is currently not available on any other fiber placement machine in the world.

Ingersoll Automated Fiber Placement Machine (AFPM)

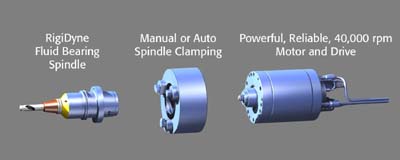

The patented RigiDyneÔ 40,000 rpm Hydrodynamic Spindle System for high velocity machining is another new development by Ingersoll. The motor drive is completely separate from the spindle, which features only seven (7) main parts. The lightweight, quick-change spindle can be switched out in less than five (5) minutes, and at just 15 kg (34 lbs.) the spindle is light enough to be shipped via express mail for service. Turnaround time for rebuilds is just one week, reducing the investment in spare spindles and downtime for spindle repairs.

RigiDyne 40,000 rpm Hydrodynamic Spindle System

Ingersoll's MultiTec machining system will make its first large-scale US debut at IMTS this year. The modular machining system combines multiple technologies—including milling, grinding, turning, turn-milling and five-axis milling—in a single machine. One MultiTec can replace several conventional machines, while eliminating multiple setups and reducing non-machining time, for overall machining cost savings of up to 80%. Five basic machine types are offered in horizontal, vertical and gantry style configurations.

MultiTec Machining System

Ingersoll's Contract Manufacturing division has recently expanded its part manufacturing capacity. Now the same reliability and precision that have gone into Ingersoll machines for over 100 years are available to accommodate outsourcing requirements for high precision complex parts. Samples of various parts machined by Ingersoll Contract Manufacturing will be displayed in the Ingersoll booth. Ingersoll Contract Manufacturing has the capability to machine large precision parts up to 4.5 M in width, weighing up to 80 tons. Ingersoll Contract Manufacturing also provides assembly services to customers who prefer to outsource complete subassemblies.

Ingersoll is a privately held manufacturer of machine tools and high precision complex parts for industrial applications around the world. The company has over 1000 employees in its North American Operations, and more than 2500 worldwide. It has manufacturing operations in Rockford, where it has been headquartered for 112 years, in addition to operations in Midland, Michigan and Germany. For more information, visit www.ingersoll.com.