Computing platform options and trends in automation and control

The selection of an "open" computer platform for automation and control applications involves a number of decisions. These include considerations of types, environmental requirements, and bus and form factor architectures. The various options for these are discussed in this paper. The paper also covers expected trends in the use of "open" computer platforms for direct control applications. Trends in network requirements also are covered.

Contents

• Introduction

• Computer hardware options

• Computer trends in industrial application and control applications

• Conclusion

Introduction

"Open" solutions covered

This paper covers options available in the selection of "open" computing platforms for industrial automation applications. These are computer solutions based on:

- Standard bus/form factor architectures

- Standard operating systems

Today we find a major shift to use of "open" computing systems. Some benefits of "open" computing systems to purchasers are:

- They can obtain compatible products from multiple sources. The competition and "economies of scale" lead to lower prices.

- With standardization, personnel training is reduced when products from different suppliers are chosen.

- Typically, with multiple sources, a wider breadth of product offerings are available, allowing more optimal product selections for the application.

- These make it easier to integrate information exchange between factory floors and executive offices.

Major platform classes

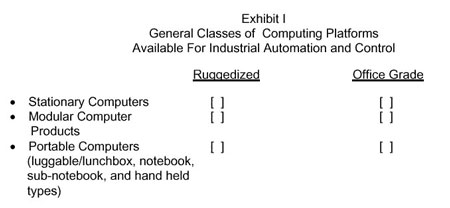

Exhibit I summarizes the major options available in the selection of "open" computer platforms for industrial automation and control applications:

Stationary versus portable choice

A very basic decision is whether the requirement is for a stationary or portable computer. Generally, the application will dictate one or the other. For example, operator interface terminal applications will typically be in dedicated use for a machine, or process, where there is no need or desire for portability. On the other hand, there are industrial applications for portable computers, such as for PLC programming, in monitoring and data acquisition, in test and measurement, and in maintenance and troubleshooting.

Assuming a stationary solution is required, the choice then becomes whether to buy a fully integrated computer, or to configure a system, purchase the modular components, and assemble the computer. Supposedly, users could also buy components and configure portable computers, but none do this.

Fully integrated stationary versus modular component choices

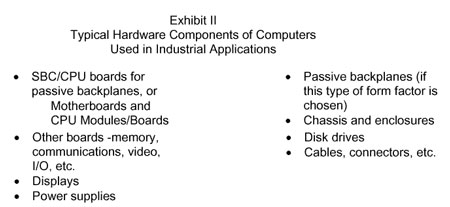

A typical computer used in industrial applications is made up of the components shown in Exhibit II.

Selecting the proper components to be integrated and assembled requires some skill. For this reason, a larger share of the modular market is with OEMs and systems integrators than is the market for fully integrated stationary computers. End users, who typically have limited design engineering capabilities, will more often opt to purchase fully integrated units.

Some other considerations in choosing fully integrated or modular component solutions are:

- Time constraints-Buying an off-the-shelf design/unit is quicker than designing and assembling components

- Price-It may cost less to buy and assemble components.

- Available merchant computers may not provide the best solution for the application for a variety of reasons, and more optimal solutions may be available by selectively choosing components.

- One Source Responsibility-In configuring his own computer, the purchaser has no single source to turn to for support on the whole computer.

- Building their own gives users greater control over the configuration-making changes is easier, there is less concern about long term availability, etc.

Portable computer choices

If the application requires mobility on the part of the user, portable computer platforms can be a cost effective solution. Luggable/lunchbox and notebook size portable computers are used in similar industrial applications; data acquisition, remote FAX servers, maintenance and troubleshooting, testing communication lines, portable database servers, mobile Internet servers, PLC programming, etc.

Luggable/lunchbox size units are the most expensive portable platform option, and for many applications, these are too heavy, bulky, or difficult to carry. Notebook computers are a more cost effective solution which offer similar performance capabilities as most luggable/lunchbox computers.

Hand held computers are the least expensive option, but offer less performance and functional capabilities than the other two. However, the power and performance capabilities of these is increasing. There is a growing trend for vendors to offer hand held computers with Windows CE and other powerful operating systems. These also are being offered with powerful microprocessors such as Pentium types. Hand held computers are ideal for remote monitoring and data logging applications in which the user cannot, or does not, want to carry around the larger and heavier notebook or luggable/lunchbox computers.

Choosing between ruggedized and office grade products

Everyone is familiar with office grade computers-the PCs on almost every office desk. But what are ruggedized computers? These are units "hardened" to withstand difficult operating environments, while providing good reliability, and long life. Some means of hardening include:

- higher reliability in system design and components-some must run 24 hours/day, seven days a week for extended periods with very low failure rates;

- power supply enhancements (regulation, surge suppression, etc.) and/or redundancy;

- sturdier cases (rack mounted, NEMA or IP ratings, etc.);

- extended operating temperature range capabilities;

- higher resistance to vibration and shock;

- intrinsically safe/explosion proof;

- liquid splash/cleaning protection;

- shielding from magnetic fields;

- EMI/RFI filters and shielding;

- higher humidity toleration;

- diagnostics and alarms; and,

- filtering of cool air.

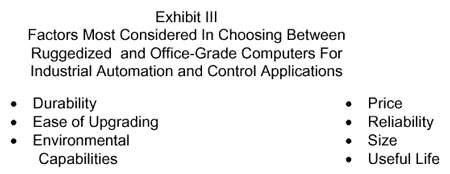

In a recent market study, Venture Development found among purchasers of computers for industrial applications that about 30% of those purchased were office grade types and 70% were ruggedized. The study also sought to determine on what basis the choices were made between these. Exhibit III summarizes the factors most often considered.

The office grade products are less expensive but do not stand up as well in factory environments, have lower reliability, and shorter operating lives. Thus, these require more maintenance, and replacement more often. For some users these limitations are entirely acceptable. They comment, "The office grade units are so cheap, if one fails, we just discard it and buy another." For some other users in more "mission critical" applications, where down time is very expensive, such an approach is unacceptable, and they almost automatically choose rugged products. Still other users try and conduct lifetime cost of ownership studies between the two methods to decide.

Complicating this decision process is the growing practice of placing office grade computers within industrial enclosures (NEMA housings, etc.) to provide some environmental protection in less harsh environments. While doing this adds to the initial price, the total typically is less than purchase of ruggedized computers.

Back to top

Computer hardware options

The following cover basic hardware choices that must be made in configuring the computers.

Passive vs active backplane

A passive backplane is a printed circuit board, or device, containing slots or sockets for plugging in boards or cables. A passive backplane contains expansion slots into which boards (such as SBC/CPU boards, I/O boards, etc.) are plugged. Passive backplanes are available in different sizes and for a variety of bus architectures.

Active backplane is a term used to describe computer architectures that use a motherboard, which is the main printed circuit board, and contains connectors that accept additional boards. The motherboard contains the bus, CPU and co-processor sockets, memory sockets, keyboard controller, and supporting chips. Chips that control the video display, serial and parallel ports, mouse, and disk drives, may or may not be present on the motherboard. If not, there are independent controllers that are plugged into the expansion slots.

Office grade computers have active backplane architectures. Both active and passive backplane architectures are used in ruggedized computers. In general, passive backplane computers are more expensive than active types, although these offer more flexibility, and ease of expansion.

Bus and form factor architectures

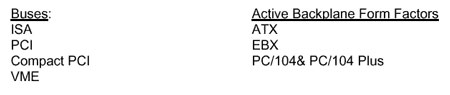

A variety of standard bus and form factor architectures are used in ruggedized computers. Some are unique to ruggedized computers, others are those also used in office grade computers, or are modifications of those used in office grade computer. The most popular ones today are:

Choosing the bus/form factor architecture should be driven by the specific demands of the application. For example, among these most popular buses, ISA has the most limited performance capability, but computers built around these will likely be the least costly. Thus, if the application specifications can be satisfied using an ISA bus, then this probably should be chosen.

It should be kept in mind, however, that the relative costs are not static. ISA boards, for example, are relatively inexpensive because the boards and components on the boards are built in large quantities. However, as volumes grow for PCI and CompactPCI products, the premiums on the prices of these boards over ISA boards will narrow. The following are brief descriptions of these buses and form factors:

Industry standard architecture (ISA) -This is a commonly used expansion bus. It accepts the plug-in boards that control the video display, disks and other peripherals. The bus has 8 or 16 bits, and most ISA bus computers provide a mix of 8-bit and 16-bit expansion slots. Because it is such a widely accepted standard, ISA bus architecture is used on ruggedized PC products. However, it is more extensively used in combination with the PCI bus.

The ISA bus has a maximum data transfer rate of 10 MHz, which is much slower than that for PCI, CompactPCI, and VME. It thus is being displaced in many new applications. Nonetheless it has a large installed application base, and a huge legacy of application software.

Peripheral component interconnect (PCI) - In the non-industrial context, PCI is a local bus for personal computers that provides a high-speed data path between the CPU and peripheral devices (video, disk, network, etc.). There are typically three or four PCI slots on the motherboard. In a PC, the PCI bus can co-exist with ISA or EISA buses. ISA and EISA boards still plug into an ISA or EISA slot, while high-speed PCI boards plug into a PCI slot. PCI comes in 32- and 64-bit varieties and runs at 33 and 66 MHz.

The PCI bus was developed by Intel for commercial PCs. However, a consortium of ruggedized PC component suppliers known as PCI Industrial Computer Manufacturers Group (PICMG) was established to develop a PCI standard for rugged passive backplanes. It provides a higher level of ruggedness in a high speed bus. With the PCI bus architecture being used in millions of PCs that ship each year, there are significant economies of scale associated with the components used on PCI computer boards, as well as a large collection of off-the-shelf software. Both of these result in significant time and cost savings.

CompactPCI - The CompactPCI bus is an adaptation of the PCI specification for rugged and embedded applications that require a more robust mechanical form factor. This was accomplished by adopting the IEEE 1101.1 mechanical specifications that were incorporated into the VME bus specifications.

CompactPCI uses standard Eurocard mechanical components and metric connectors, providing a system optimized for rugged applications. It is electrically compatible with the PCI specification 2.1 (33 MHz), allowing use of inexpensive PCI integrated circuits (ICs) and software. A CompactPCI board uses a shielded 2-mm metric pin and socket connector and can be front-loaded into a rack-mount system.

CompactPCI boards have connector card guides on both sides that firmly hold the boards into position, and also have a faceplate with an injector/ejector mechanism. The boards can be solidly screwed into the card cage. Boards are mounted vertically, allowing for natural convection cooling, which is often assisted by forced air cooling. Also, the pin-and-socket connector of CompactPCI boards is considered to be more reliable than the edge connector of standard PCI boards. Unlike standard PCI, the power and signal pins on the CompactPCI connector are staged to let the specification support hot swapping, a feature that is very important for fault-tolerant and high-availability systems. CompactPCI provides a chassis design which will accommodate a large number of lines coming in the back, allowing unrestricted card insertion and card swapping in the front of the chassis.

VersaModule Eurocard (VME) - This a 32-bit bus standard developed by Motorola, Signetics, Mostek, and Thompson CSF. VME64 is an expanded version that provides 64-bit data transfer and addressing. The VME bus has been in existence for 17 years. It was originally developed to provide a robust high speed bus for real-time embedded computer applications. It remains today the most extensively used bus for embedded applications, with large shipments of VME-based computer products for military/defense, communications, and industrial automation equipment.

The VME standard adopted the Eurocard physical standard, which is part of the IEEE 1101.1 specification. These boards use a 96 pin connector rather than edge connectors. In the Eurocard standard, size 3U boards are about 4 inches high by 6 inches deep, and 6U boards about 9 inches high by 6 inches deep.

Over the years, the capabilities of VME have been extended, particularly the bandwidth. Burst mode capabilities of 160 MB/sec. has been achieved, versus a theoretical value of 132 MB/sec. for CompactPCI. CompactPCI possesses fundamental bandwidth limitations which reside in its data propagation delay. VME does not possess such a constraint. In addition, VME has a true 21 slot capability, and it possesses a true multiprocessing capability in which any slot can become the master.

VME is well-suited to run with real-time operating systems such as Lynx, OS/9, pSOS+, VxWorks, etc. The VME computer product market is dominated by Motorola, and it is not surprising, therefore, that the most used microprocessors are Motorola types, such as PowerPC models. However, these will not run Windows NT, the dominant operating system for industrial automation applications.

ATX - This is a widely used standard motherboard form factor. These boards are 12 inches wide by 9.6 inches in length. This form factor provides feature and performance enhancements over earlier standards such as:

Embedded Board Expandable (EBX) - This standard form factor developed out of the need for smaller motherboards, particularly for embedded applications. These boards are 5.75 inches wide by 8 inches long, and have around 50% the surface area of conventional motherboards. The EBX specification principally defines physical size, mounting hole patterns, and power connectors. It does not define processor type, or electrical characteristics.

EBX boards are small enough for deeply embedded applications, yet large enough to perform as powerful single board computers, capable of running the full range of available operating systems. EBX motherboards offer expansion through various board types, including PC/104, PC/104-Plus, and PCMCIA.

PC/104 & PC/104 Plus - The PC/104 standard was developed in response to increasing need to have a small PC architecture for embedded applications. Companies that embed microcomputers as controllers within their products use the PC architecture because of the savings this can bring in terms of development costs, risks, and time.

The PC/104 form factor is a more compact implementation of the PC bus, offering the entire architecture, hardware and software compatibility with the PC bus, but in 3.6" x 3.8" stackable modules. There are four key differences between PC/104 and the regular PC bus. These are: compact form-factor, self-stacking structure, pin-and-socket connectors (64- and 40-contact male/female headers replace the standard PC's edge card connectors), and relaxed bus drive (6 MA).

PC/104 has only an ISA bus. PC/104 Plus has both an ISA and PCI bus.

Back to top

Computer trends in industrial automation and control applications

Direct control

"Open" computing platforms first found use in factory automation for communication, data acquisition, monitoring, and operator interface applications. Use in direct real-time process and machine controls has been limited by the non-deterministic modes of much of the software offered, and the perceived unreliability of the software and hardware. This is changing. Significantly aiding the growing adoption is the effort of software suppliers who are providing soft PLC and soft DCS solutions for "open" computer architectures and networking protocols.

We expect that use of "open" computing platforms in direct control applications will more than double over the next 5 years. Despite this trend, however, shipments of proprietary DCSs and PLC systems are expected to continue to grow. In response to the challenges posed by "open" computing solutions, proprietary DCS and PLC vendors have been enhancing their products by providing more flexibility, scalability, connectivity, and easier programming.

In addition, there are other considerations that favor continued procurement of these proprietary products. For one, designers of industrial automation equipment are very conservative, and reluctant to readily adopt new controls. Also, for existing plants, the selection of equipment similar to what they currently have results in minimizing or eliminating retooling, and retraining of personnel.

Networking

The trend in industrial automation and control is to provide digital network interfacing across all levels of operation; from sensors, actuators and controllers, to operator interface terminals, to supervisory controls, and on back to the executive office. Reasons for this trend include:

- Enhanced productivity through more effective resource allocations, planning, and therefore, a reduction in costly inventory, scrappage costs, and greater employee productivity.

- An ability to improve quality control over the entire process - manufacturing, procurement, product quality, employee morale, strategic planning of resources and staff, and quicker time-to-market capabilities.

- The synergies obtained when integrating various departmental functions - manufacturing, engineering, purchasing, finance, accounting, etc., which raise the overall productivity and profitability of the firm. Ideas are shared, not hoarded, thereby increasing the opportunity "universe" for a company to grow its business.

- Through integration, managers can turn "raw data" from the factory floor into information which can be acted upon tactically and strategically, thereby increasing the company's competitive capabilities.

Companies realize they can no longer operate with "separate functional fiefdoms" which historically did not share ideas, information, or best practices. In today's global economy, companies must leverage all of their resources and personnel towards achieving common goals. These goals can be best achieved through company integration, not just factory integration.

At the higher computer-to-computer levels, in the factories, and between the factories and executive office, Ethernet is and will be the most used network. However, at the control level, i.e. in interfacing sensors, I/O modules, actuators, controllers, operator interfaces, etc., there are a multitude of "open" standard and proprietary networks being used. It is unclear which will prevail, although VDC's market research indicates the following are likely to gain the most prominence for use with "open" computer platforms:

DeviceNet - This is a Controlled Area Network (CAN) bus adaptation developed by Allen-Bradley. Usage of DeviceNet has expanded rapidly since introduction in 1994. Allen-Bradley gave up ownership of DeviceNet, and it is now the trademark of the Open DeviceNet Vendor Association (ODVA).

Ethernet - Well-established in business networking use, and in higher level factory networking, Ethernet is penetrating to the control network level. There are concerns about the non-deterministic nature of the network for real-time mission critical applications. However, there are many applications where this is not a concern. In addition, these may be overcome by implementing separate networks with fewer nodes.

Profibus Decentralized Peripheral (DP) - This bus standard had its origins in a joint initiative between automation manufacturers, users, academic institutions, and the German government in 1987. The principal developer of Profibus DP was Siemens. Profibus DP is part of a family of three buses. Profibus Field Message System (FMS) is a higher level bus designed principally for use between controllers, computers, and higher level nodes. Profibus Process Automation (PA) is an intrinsically safe bus which has much the same protocol as the DP, but the electrical specifications are modified to satisfy low voltage and current requirements for intrinsic safety.

Back to top

Conclusion

Users today have a variety of options from which to choose an "open" computing platform for automation and control applications. "Open" computing platforms are available in either ruggedized or non-ruggedized forms for a variety of applications. Modular components can be purchased in order to design a system for specific needs. In addition, this is usually a lower cost alternative to purchasing a complete, fully integrated unit.

For users requiring mobility, there are several portable computer options from which to choose from. There are notebook, lunchbox, luggable, and hand held types which can serve a variety of needs at varying prices.

With all of these, users can choose from an array of microprocessors, bus architectures, operating systems, and related components at varying degrees of performance and price. In the final analysis, choosing the best "open" computing platform option is based on a careful assessment of the needs and requirements of the application(s) being utilized. Choosing in this manner will satisfy the need and also help insure not paying for unneeded "bells and whistles".

Back to top

About the author

Maurice Klapfish is VP of Venture Development Corp. (Natick, MA).

This article is provided courtesy of the ISA - the Instrumentation, Systems, and Automation Society.