Advanced control integration made easy

The application of advanced control tools in a traditional control system is often complicated by the lack of standard tools for integration. The recent introduction of OPC support by some control system suppliers has simplified the job of accessing information within the control system. In addition, the structure of some modern scalable control systems allows operator and engineering interfaces to be easily constructed from standard function blocks and display components for advanced control applications. In this paper, we review how such tools may be used to provide an implementation that provides many of the benefits as well as ease of use associated with embedded features of the control system. As an example, the integration of the SMOC multi-variable control package into the DeltaV control system is presented. In particular, the approach taken in the development of a standard OPC client interface to the control system OPC server is described. Details are provided on how engineering and operator station interfaces have been created using composite blocks and standard display components. The steps involved in addressing a control application in this environment are illustrated using this example.

Contents

• Introduction

•Accessing control system information

• Representation of application information

• Integration example

• Conclusion

• References

Introduction

Many of the modern advanced control tools used with traditional, distributed-control systems have been implemented as a layered application [1], [2]. Typically, the provider of this technology is not the control system manufacturer. Thus, the suppliers of this technology have had to design their products to interface with a variety of control systems. Only recently has the processing power available in embedded controllers reached the point where multi-variable control for a process unit may be embedded at the controller level. [3] The communication and processing power requirements for cross unit advanced control and optimization often require that they be implemented as layered applications. However, many of the integration problems that have previously limited the use of layered advanced control applications are being addressed by modern scalable control systems. The tools available in such systems allow advanced control applications to be integrated in such a manner as to provide many of the features of an embedded control application.

The function block support and open communications of modern scalable control systems provide the following capabilities:

- A means for advanced control applications to access information within the control system that is independent of the manufacturer

- The ability to easily create new function block structures that may be used to reflect information in the application and make that information accessible within the control system

When these features are applied in the integration of advanced control applications, there is an ease of use that is comparable to embedded control system features. In this paper, we explore this new capability to access and represent information within the control system and illustrate how these features have been used to integrate a leading MPC application into a modern scalable control system.

Back to top

Accessing control system information

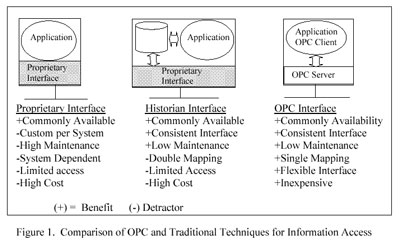

The interface that many control system manufacturers provide to access information within the control system is proprietary. Even though some manufacturers have adapted a communication physical and data link layer standard such as Ethernet, the communications protocol is often unique to the manufacturer. Therefore, the manufacturer of products that are commonly used with a variety of control systems must develop and maintain interface software for each control system. To avoid the need to develop and maintain such interfaces, some advanced control applications access control system information through a data historian package that supports interfaces for variety of control systems. However, such an approach introduces some restrictions in implementation. Also, the dual mapping of information required for the historian and the application can increase engineering and maintenance costs.

Within the last few years, the OPC standard for information access has gained wide acceptance within the process industry. Some modern scalable control systems utilize OPC as the primary means for accessing information within the control system. Often, such capability is provided at a fraction of the cost of proprietary interfaces. Once an application has been structured as an OPC client, it may work with the OPC server supported by any control system. Such standardization allows the same application to be installed on different control systems with little or no change in the OPC client implementation. The use of OPC for information access eliminates the need to develop and maintain different interfaces for each major control system supplier. Also, OPC often provides additional flexibility in the data types and speed with which information is accessed. For example, in some installations it has been shown that OPC can access information at rates exceeding 60,000 attribute values/second. Such performance, combined with the ease in configuration, offers many advantages over the traditional integration of layered applications, as summarized in Figure 1.

Representation of application information

A layered application that uses an OPC interface may efficiently read and write the measurement, calculation, and configuration values within the control system. However, the configuration, operation, and maintenance information that is contained within the layered application may only be available through a dedicated engineering interface. The ability to also provide this information within the control system is often limited by the rigid structures supported by the control system, some modern control systems support the creation of new function block structures. Such capability may be used to hold application information so that it may be accessed within the control system.

The function block is often the primary means of representing control, calculation, and measurement information in a control system. If a system has the capability to create and add new function block structures, then it is possible to use these blocks to reflect the information contained in a layered application. Often, the number of parameters, name, and data type/structure associated with the function block may be defined to match the organization of data within the application. If this capability is used to make application information visible within the control system, then standard control system features may be used to configure the layered application and create operator interfaces for viewing and interacting with the application.

Back to top

Integration example

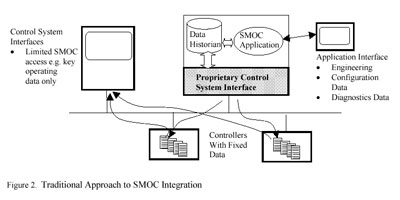

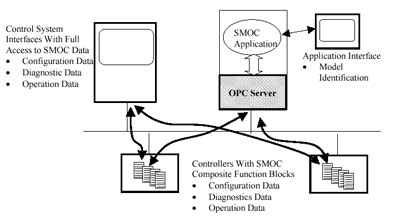

The OPC support and flexible function block capability available in modern control systems may be used in the integration of advanced control applications. One such example is the integration of the Shell Multi-variable Optimizing Control(SMOC) application into the DeltaV control system. This advanced control application is installed in over 350 processes, many of these being layered applications on a variety of traditional control systems. The recent integration of this product takes full advantage of the application OPC interface as well as the control system's OPC support and flexible function block capability. The benefits of this approach are best illustrated by contrasting this recent implementation to the traditional approach previously used to integrate this application. Many of the early installations of the SMOC application utilize the proprietary interface provided by the control system manufacturer. However, the practical consideration of supporting this application on multiple control systems led to installations in which this application was integrated through the data historian. This approach eliminates the need for the SMOC application to support the control system's proprietary interface. In many of the installations involving traditional control systems, there was no support to create new structures to reflect the configuration and operation data contained within the SMOC application. Thus, any data that was needed in the control system interface had to be mapped to standard structures available in the control system. Because of the complexity and time required to do this mapping, only key operating data parameters may be available to an operator through his normal control system interface. Diagnostic and configuration data associated with this application were only be available through an application interface. Such an installation is represented below:

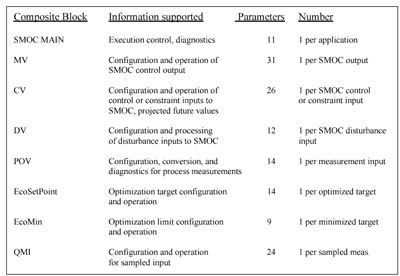

From the standpoint of convenience, it is desirable to have the entire configuration, diagnostic, and operation data associated with the SMOC application available within the control system. This data may then be accessed using standard system capability. Using the capability of a modern scalable control system, custom composite function blocks have been defined to reflect the configuration, diagnostic, and operation data within the SMOC application. This data has been grouped into composite function blocks in the following manner:

The composite blocks for SMOC integration were created using the standard drag-and-drop features of the control system. Once these composites blocks are loaded into a control system, modules that represent SMOC control applications may be created using the standard tools in the system. The parameters of these composite blocks represent both configuration and operations data used in the SMOC application. To provide consistency with older SMOC implementations, the parameter data type, names, and access protection were defined to match existing SMOC implementation. Thus, if a person is familiar with a traditional installation of SMOC he can quickly become familiar with the SMOC composite blocks.

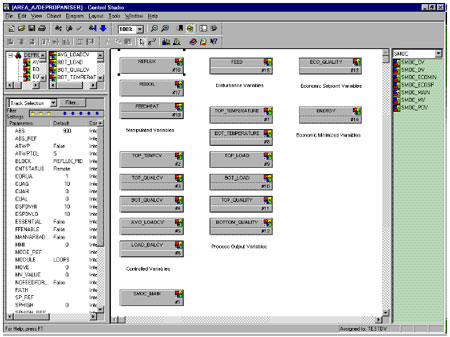

Using the composite blocks created for the SMOC application, it is possible to quickly define control application by creating a module that uses these composite blocks. Based on the control requirements of the process, drag-and-drop techniques may be used to add the appropriate number of composite blocks to the module. The tag defined for each composite block may be configured to show its function and associated loop tag. Some of the parameters included in the composite blocks are defined as dynamic references. This capability allows the composite bock to access parameters in other I/O or control blocks that interface with field measurement or provide base level control. Once a module for a SMOC control application has been configured and downloaded to a controller, this module may be accessed through standard operator interfaces and engineering tools throughout the control system. The ability to view, trend, alarm, and interact with composite block parameters is the same as that provided for standard blocks within the control system. For example, the engineering tools used to examine the parameters of a module as it executes in the controller may be used with a module containing composite blocks. The following shows a module that was created for SMOC control of a depropaniser.

When the SMOC application is structured as an OPC client, it may read and write the parameters of the composite blocks residing in the controller. The configuration parameters required by the SMOC application are read from the composite block when the application first executes. New parameter values are automatically reported to the SMOC application. Similarly, the operating parameters defined in the composite blocks are continually updated by the SMOC application. Parameters associated with process measurements and control action are defined in the composite as dynamic references. These parameters are automatically written to or read from the associated I/O or control blocks within the control system.

The only parameters that must be defined when engineering a SMOC application are the tag of the module and the tags of the composite blocks contained in that module. Since the parameters associated with each type of composite block used in the SMOC application are standardized, this information does not have to be configured.

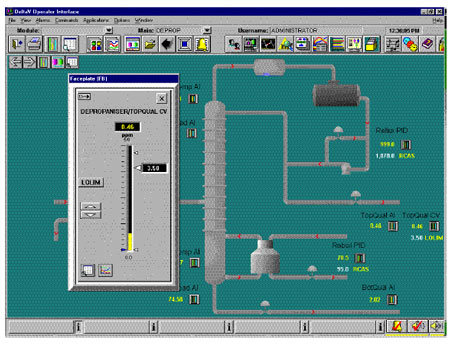

Similarly, the use of standardized composite blocks within the control system containing SMOC configuration data, process measurements, and control actions enables a library of standard operator faceplates to be constructed. This library contains one faceplate for each type of composite. The construction of operator displays is then a simple matter of dragging the relevant faceplate to a display from a palette and browsing to associate it with the corresponding composite block. This means that embedded control information and advanced control information are both available to operators through the same interface, as illustrated in the following example.

The information flow between the SMOC application and the control system may be visualized as follows:

Conclusion

New tools exist in modern scalable control systems that facilitate the integration of layered advanced control applications into the control system. It is possible to create new types of function blocks within the control system that reflect the application configuration and operation data. Through the use of OPC, this information may be efficiently accessed by the application. Using these techniques, the operation and configuration information contained in a layered advanced control application may be made available within the control system. This approach allows application information to be accessed with an ease of use normally associated with embedded features of the control system.

Back to top

References

1. Garcia, C.E., Prett, D.M. and Morari, M., "Model Predictive Control: Theory and Practice – ASurvey," Automatica, 25(3):335-348, 1989.

2. Froisy, J.B., "Model Predictive Control: Past, Present and Future," ISA Trans. 33: 235-243, 1994.

3. Wojsznis, K.W., and Wojsznis, P.W, "Robust Predictive Controller in Object-Oriented Implementation," Advances in Instrumentation and Control, Volume 48, Part 1, pg.521, 1993.

4. DeltaV TM Home Page: http://www.EasyDeltaV.com

5. MDC Technology Home Page: http://www.mdctech.com

Back to top

About the authors

Terry Blevins is principal technologist at Fisher-Rosemount Systems in Austin, TX. David McCaffrey is product manager of MCD Technology in England.

This article is provided courtesy of ISA - the Instrumentation, Systems, and Automation Society.

Back to top